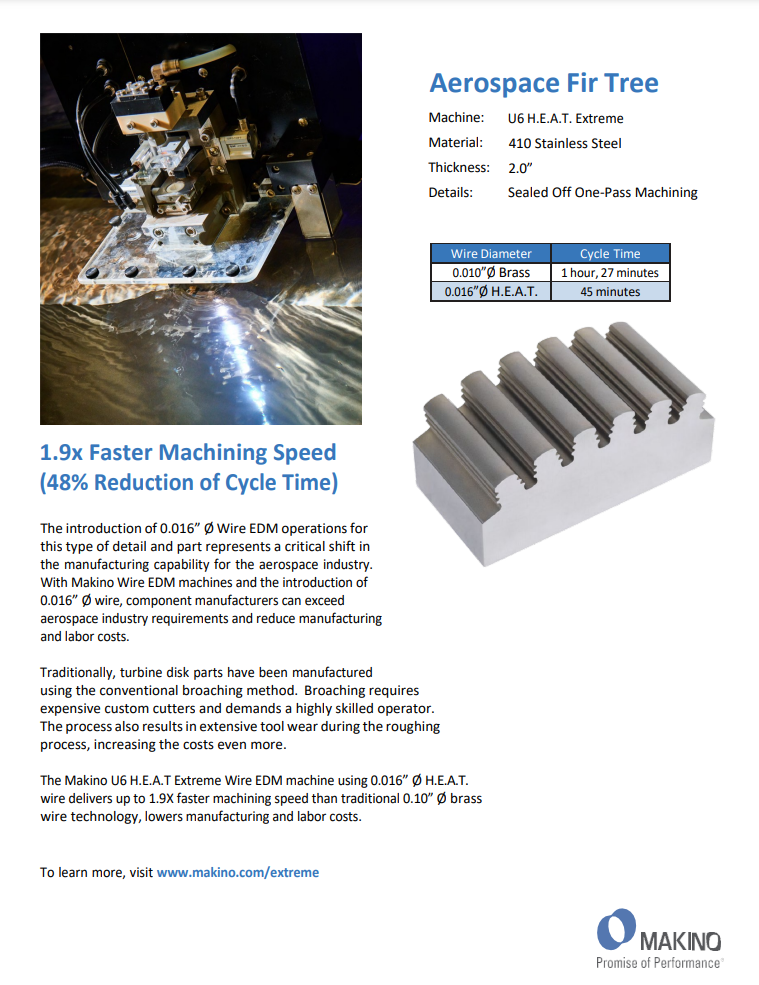

Case Study Aerospace Fir Tree

The introduction of 0.016” Ø Wire EDM operations for this type of detail and part represents a critical shift in the manufacturing capability for the aerospace industry. With Makino Wire EDM machines and the introduction of 0.016” Ø wire, component manufacturers can exceed aerospace industry requirements and reduce manufacturing and labor costs.

Traditionally, turbine disk parts have been manufactured using the conventional broaching method. Broaching requires expensive custom cutters and demands a highly skilled operator. The process also results in extensive tool wear during the roughing process, increasing the costs even more.