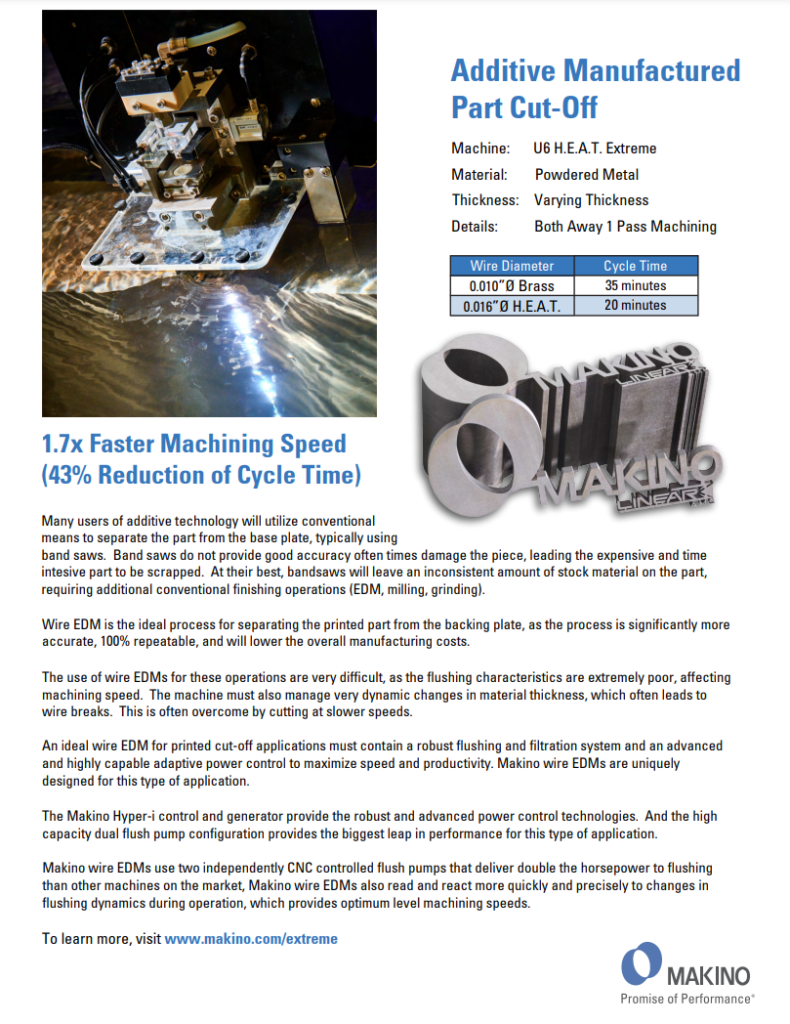

Case Study Additive Manufactured Part Cut-Off

Many users of additive technology will utilize conventional means to separate the part from the base plate, typically using band saws. Band saws do not provide good accuracy often times damage the piece, leading the expensive and time intesive part to be scrapped. At their best, bandsaws will leave an inconsistent amount of stock material on the part, requiring additional conventional finishing operations (EDM, milling, grinding).

Wire EDM is the ideal process for separating the printed part from the backing plate, as the process is significantly more accurate, 100% repeatable, and will lower the overall manufacturing costs.